Plastic Cap Mold Revolution: The Future of Packaging is Here

2025-02-24 | plast blog

Plastic Cap Mold Revolution: The Future of Packaging is Here

The packaging industry is undergoing a transformative shift, driven by advancements in **injection mold for caps** technology. This innovation is not just a step forward; it’s a leap into the future of packaging solutions. With sustainability, efficiency, and precision at its core, the plastic cap mold revolution is reshaping how products are sealed, stored, and delivered.

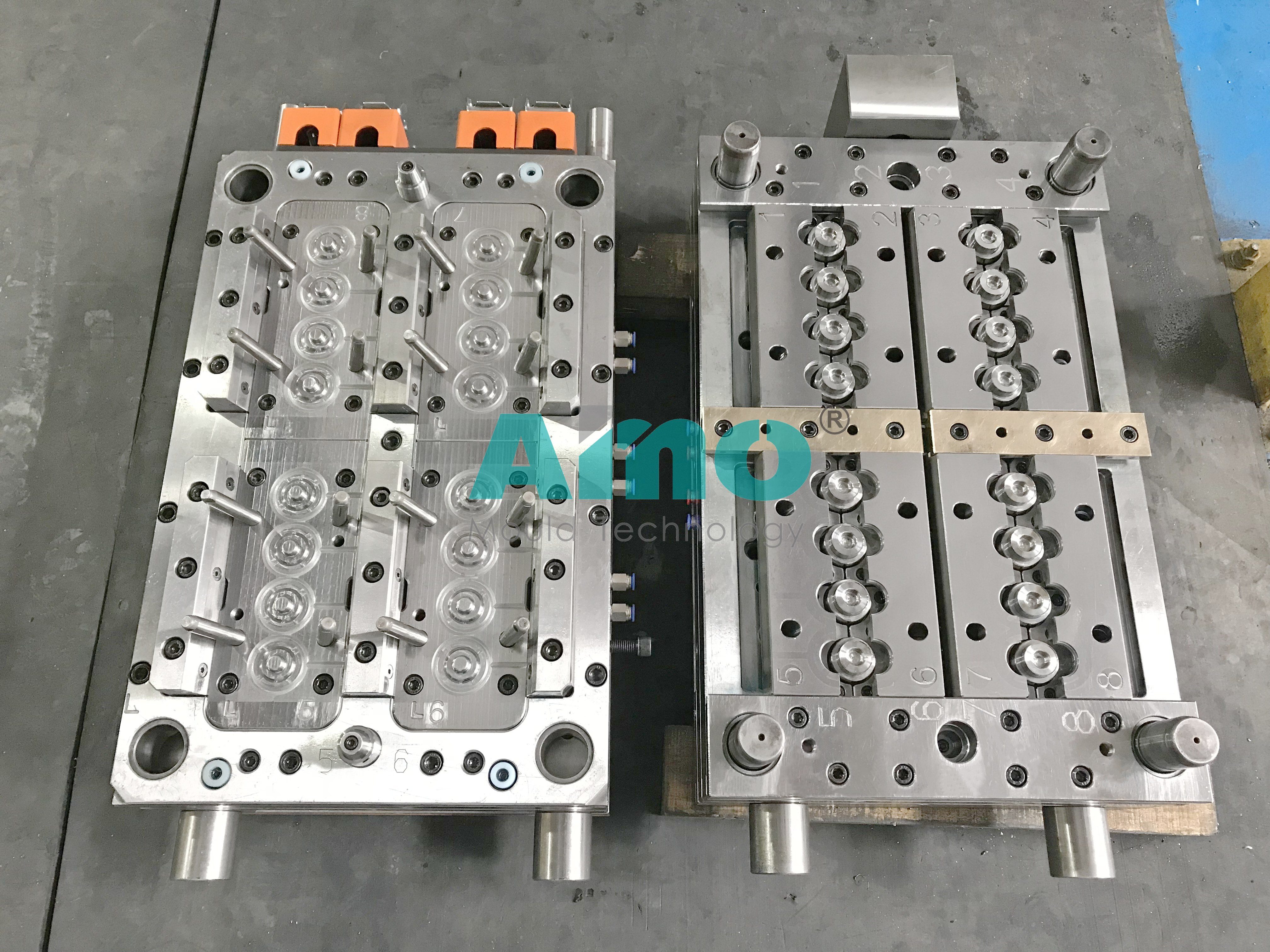

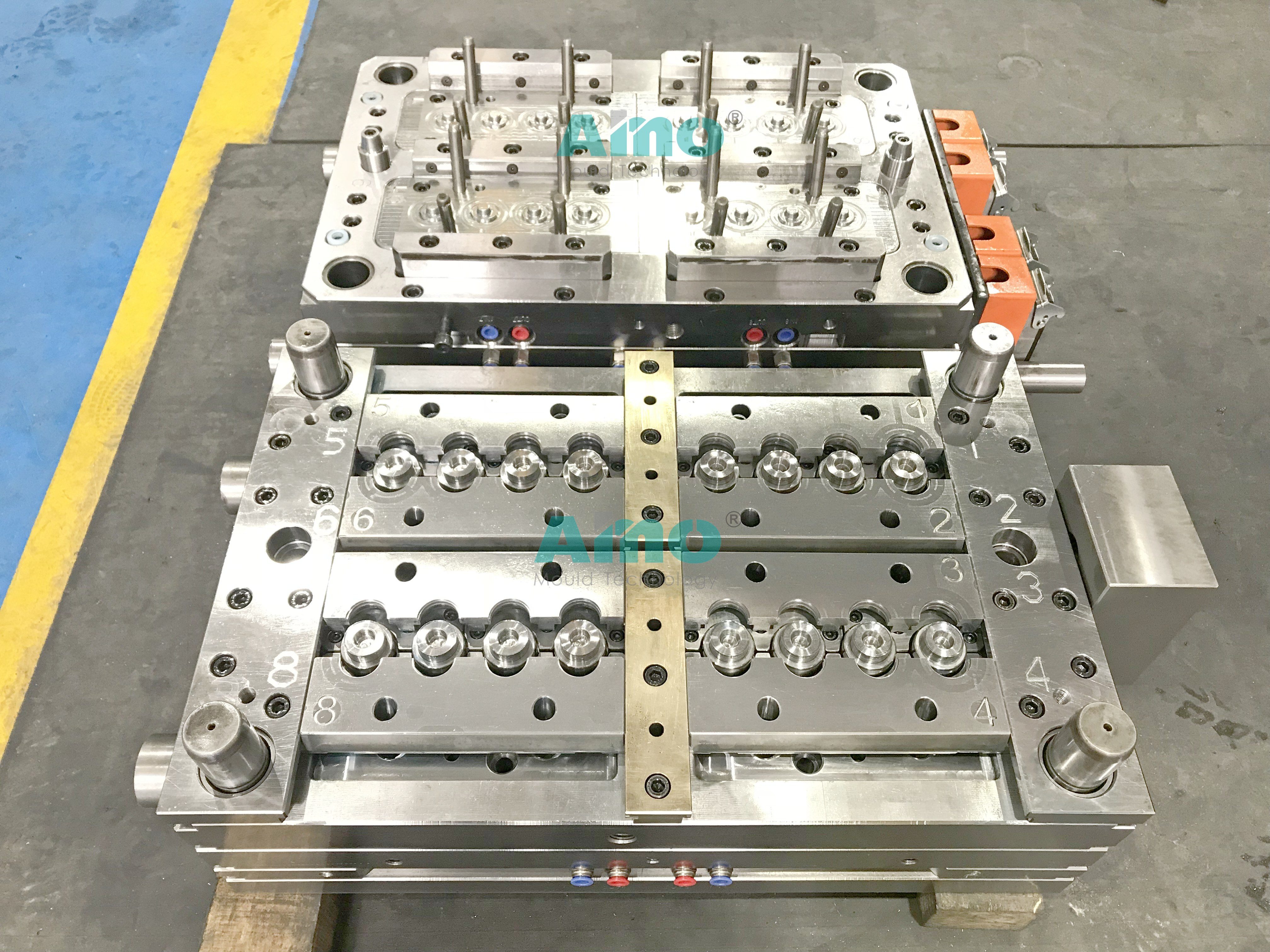

Injection mold for caps has become the cornerstone of modern packaging. This method allows for the mass production of high-quality, durable, and customizable caps with unmatched precision. Manufacturers can now produce caps that fit perfectly, ensuring airtight seals and reducing waste. The process is also highly efficient, minimizing material usage and energy consumption, which aligns with the growing demand for eco-friendly packaging.

One of the most significant advantages of this technology is its versatility. Whether it’s for beverage bottles, pharmaceutical containers, or cosmetic products, injection mold for caps can be tailored to meet diverse industry needs. The ability to create intricate designs and incorporate branding elements directly into the caps adds a new dimension to product presentation.

Moreover, the speed and scalability of injection molding make it a cost-effective solution for businesses of all sizes. As the demand for sustainable packaging grows, this technology is poised to play a pivotal role in reducing plastic waste and promoting circular economy practices.

The plastic cap mold revolution is here, and it’s clear that the future of packaging is smarter, greener, and more efficient. With injection mold for caps leading the charge, the industry is set to meet the challenges of tomorrow head-on.

Related News

contact us

Get a Free Quote

Our engineers are available to talk you through each of our offerings. We’ll be sure to reply you within 48hours with detail quotation data. Fill in the form below with as much detail as possible, we’ll get back to you promptly.

SUBMIT