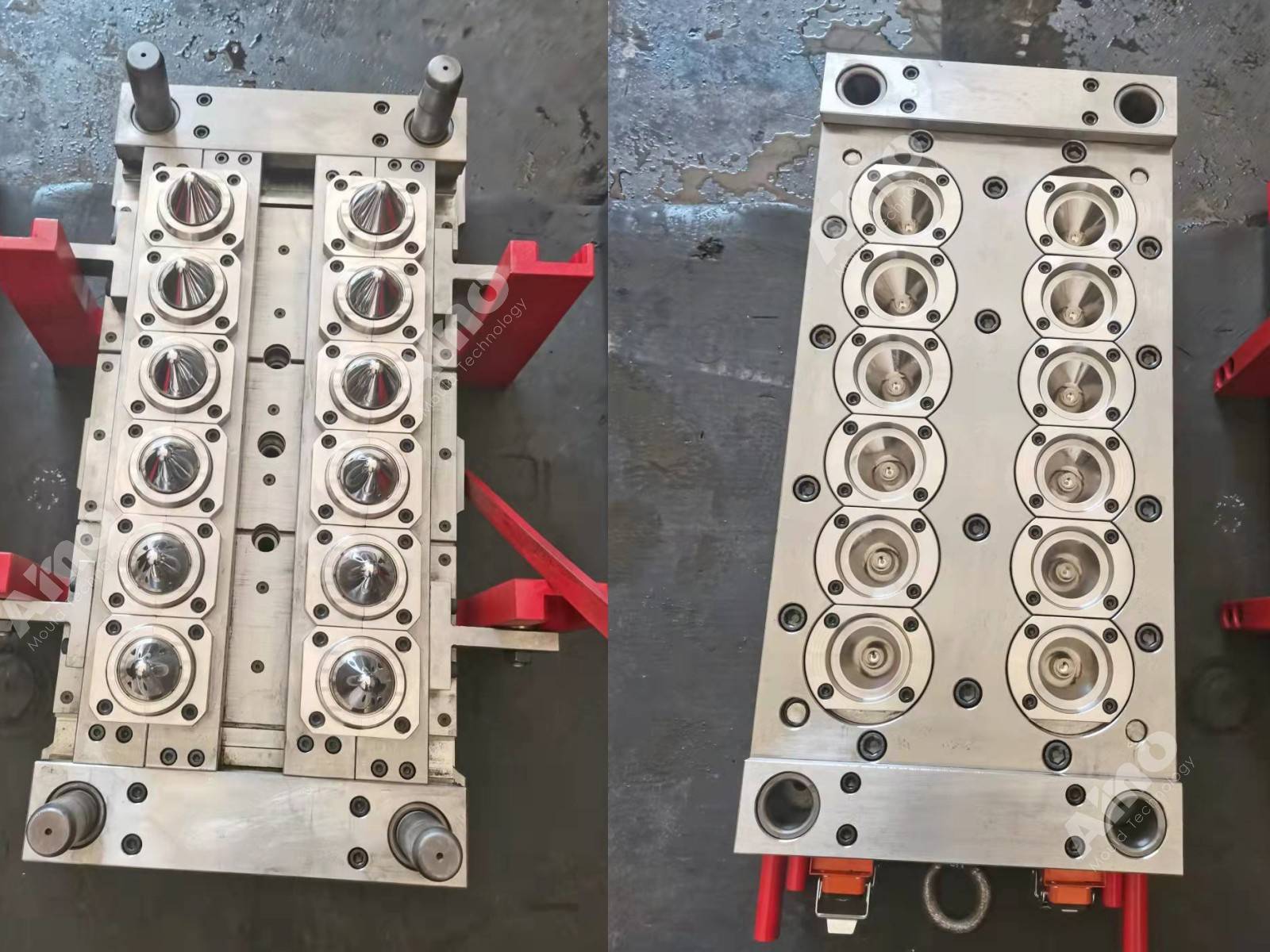

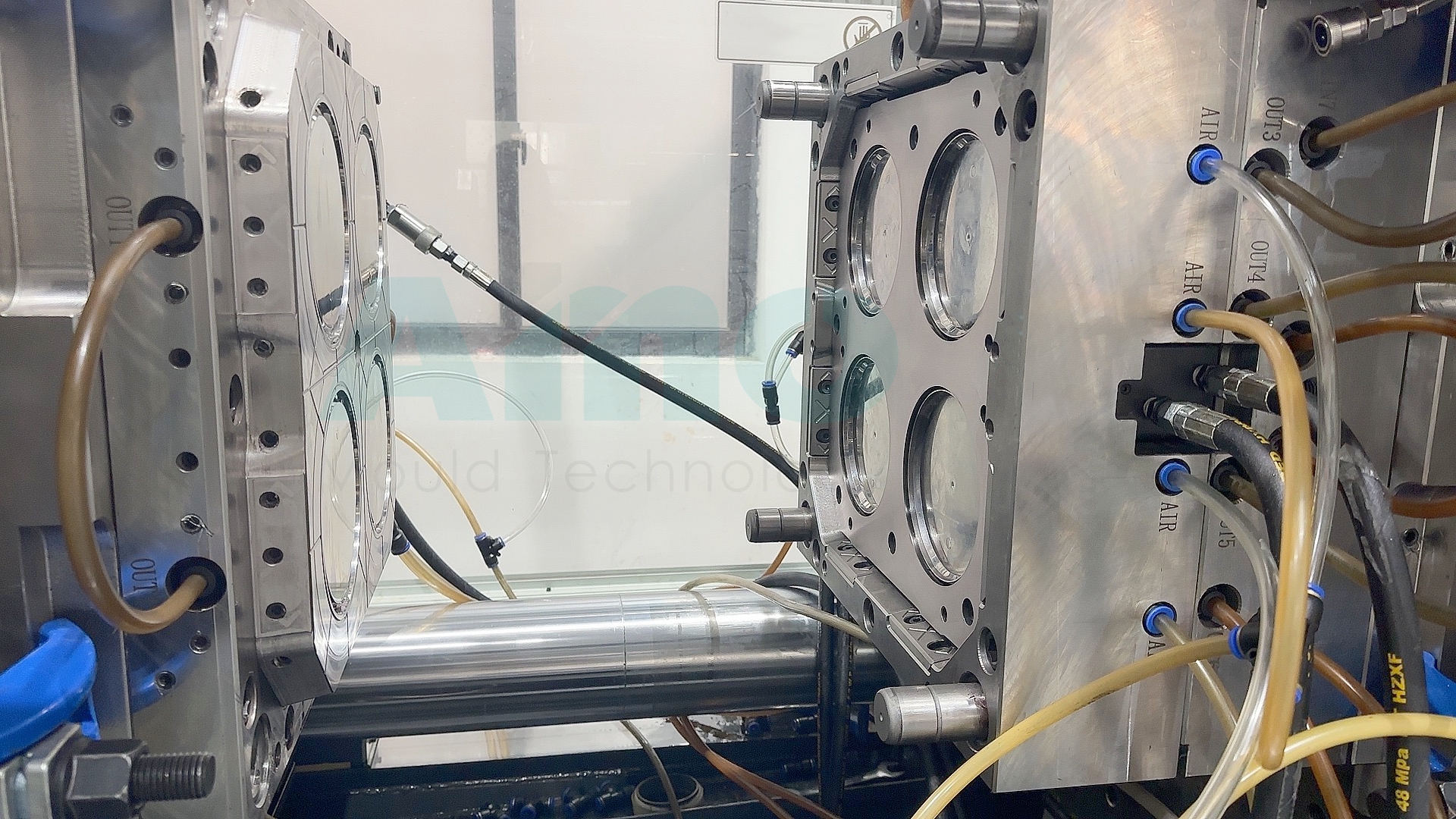

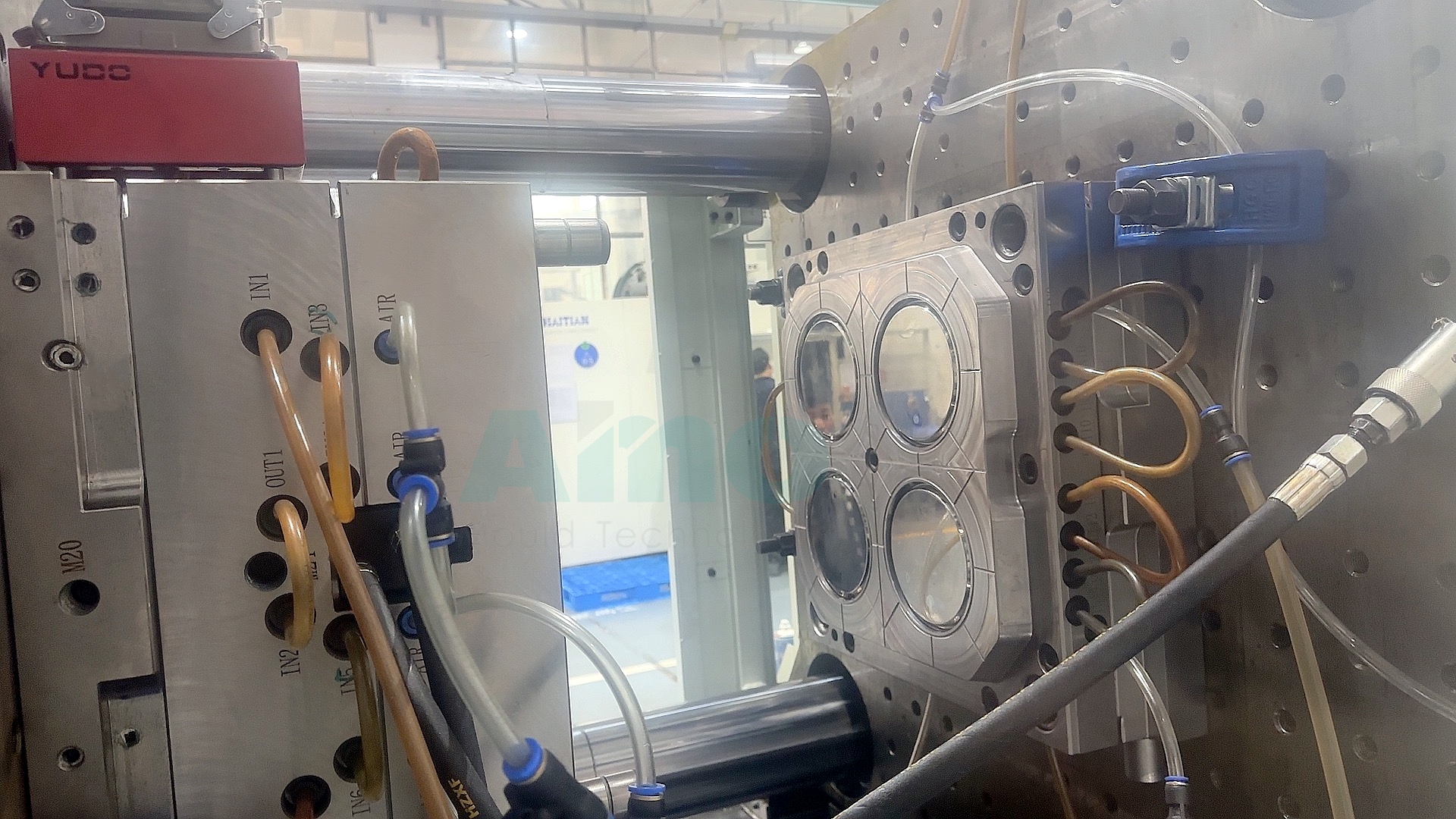

750ml Cost-Effective Thinwall Lid mold

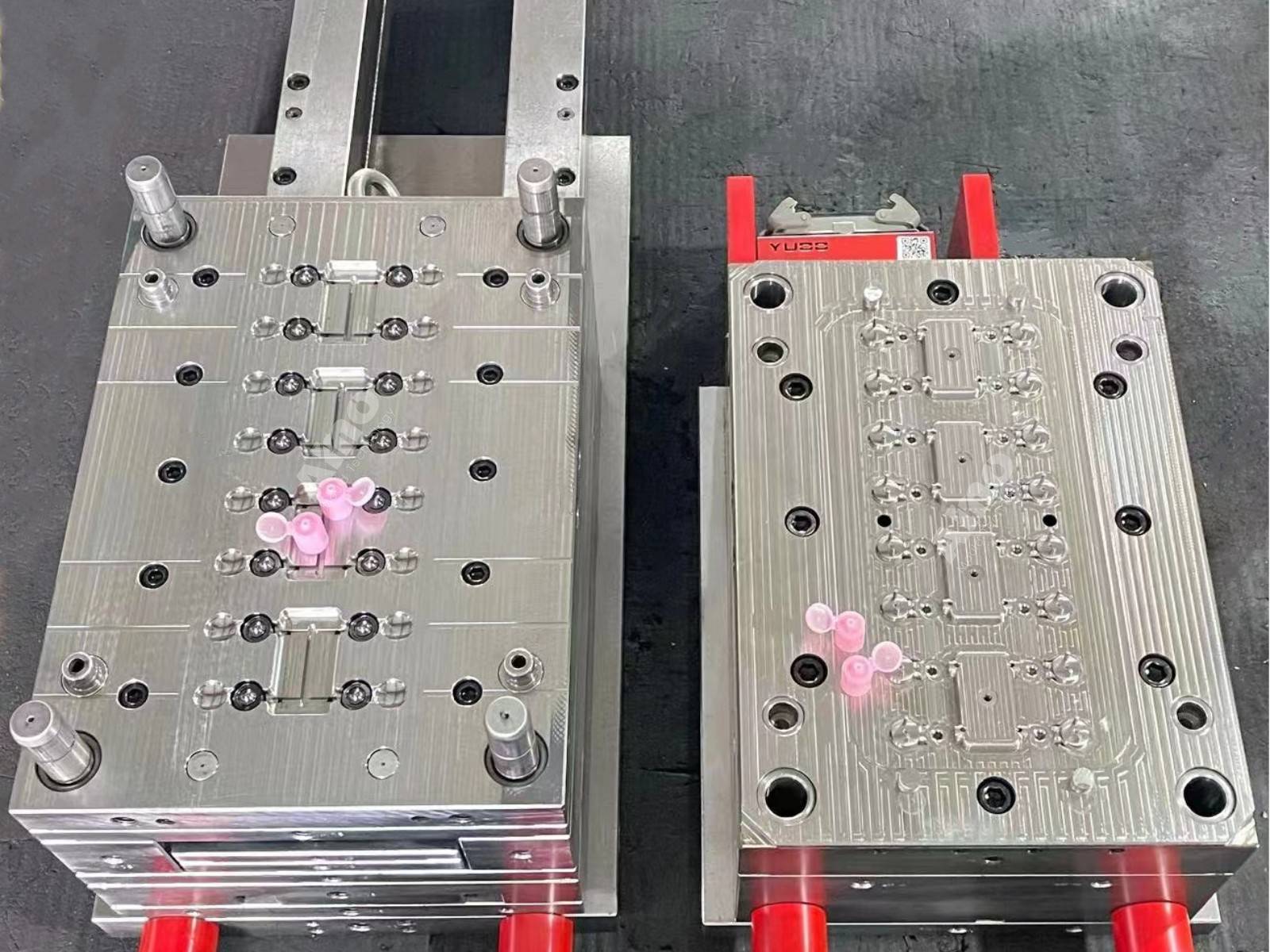

thinwall bucket lid mold

Thinwall lid molds achieve zero-defect outputs via CMM precision, advanced tooling, and optimized hot runner systems for flawless production.

Inquiry Now

Descriptions

Ultimate Guide to High-Precision Thinwall Lid Molds: From CMM Measuring to Zero-Defect Outputs

High-precision thinwall lid molds are revolutionizing industries like food packaging, electronics, and automotive sectors by enabling lightweight, durable, and cost-efficient production. Achieving zero-defect outputs demands cutting-edge engineering, rigorous quality control, and advanced technologies like CMM measuring and hot runner systems. Here’s how to master the process:

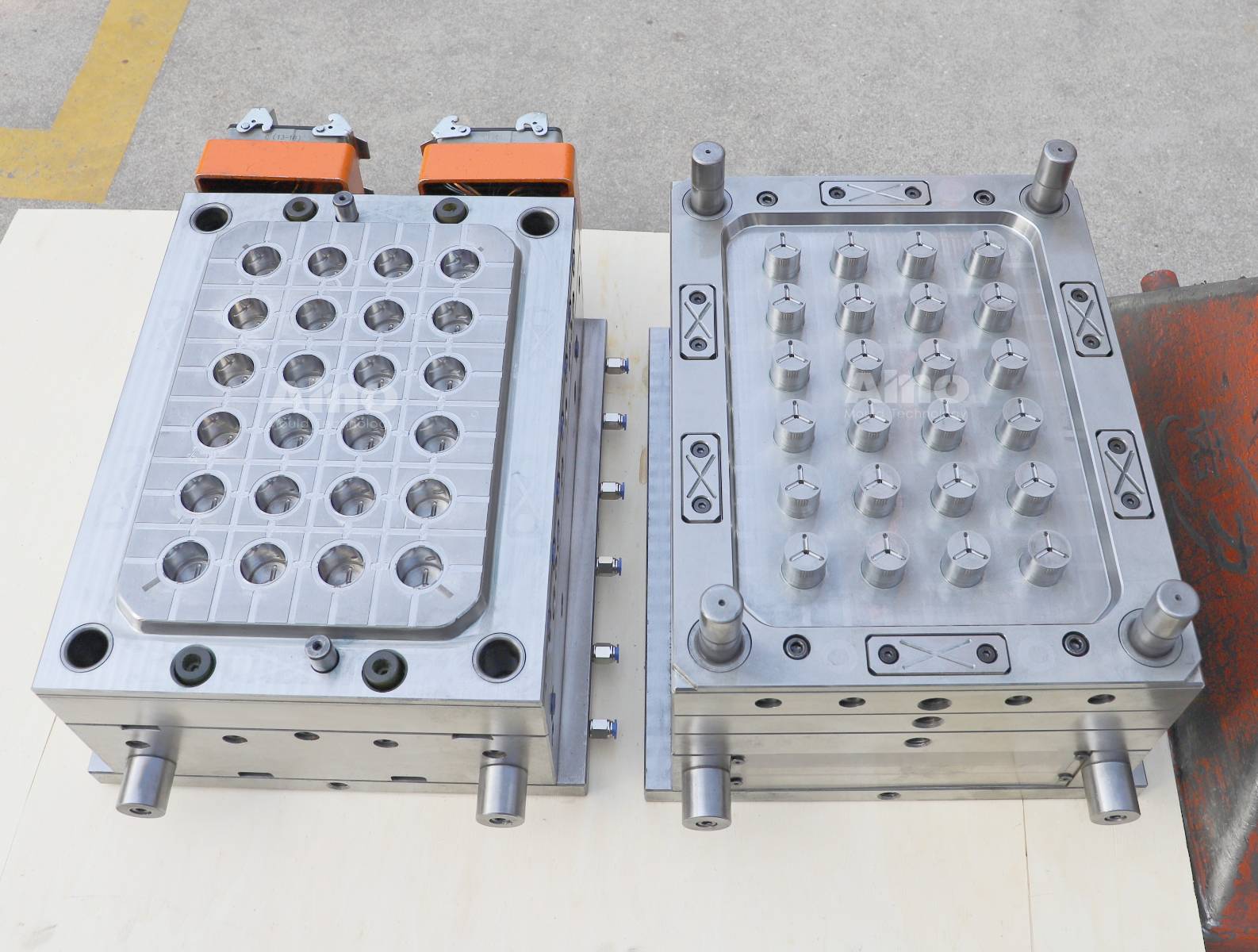

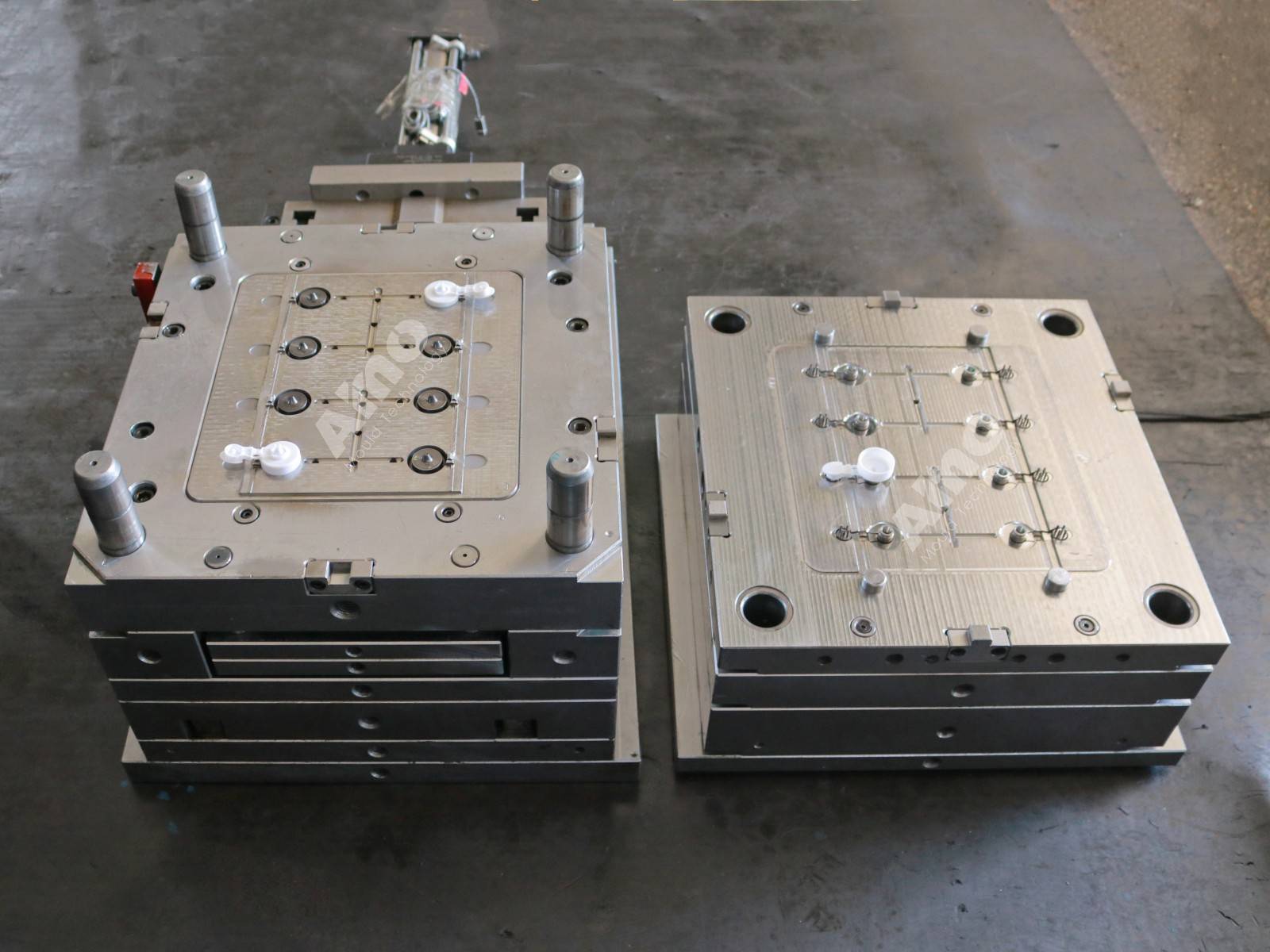

1. Precision Design & Tooling

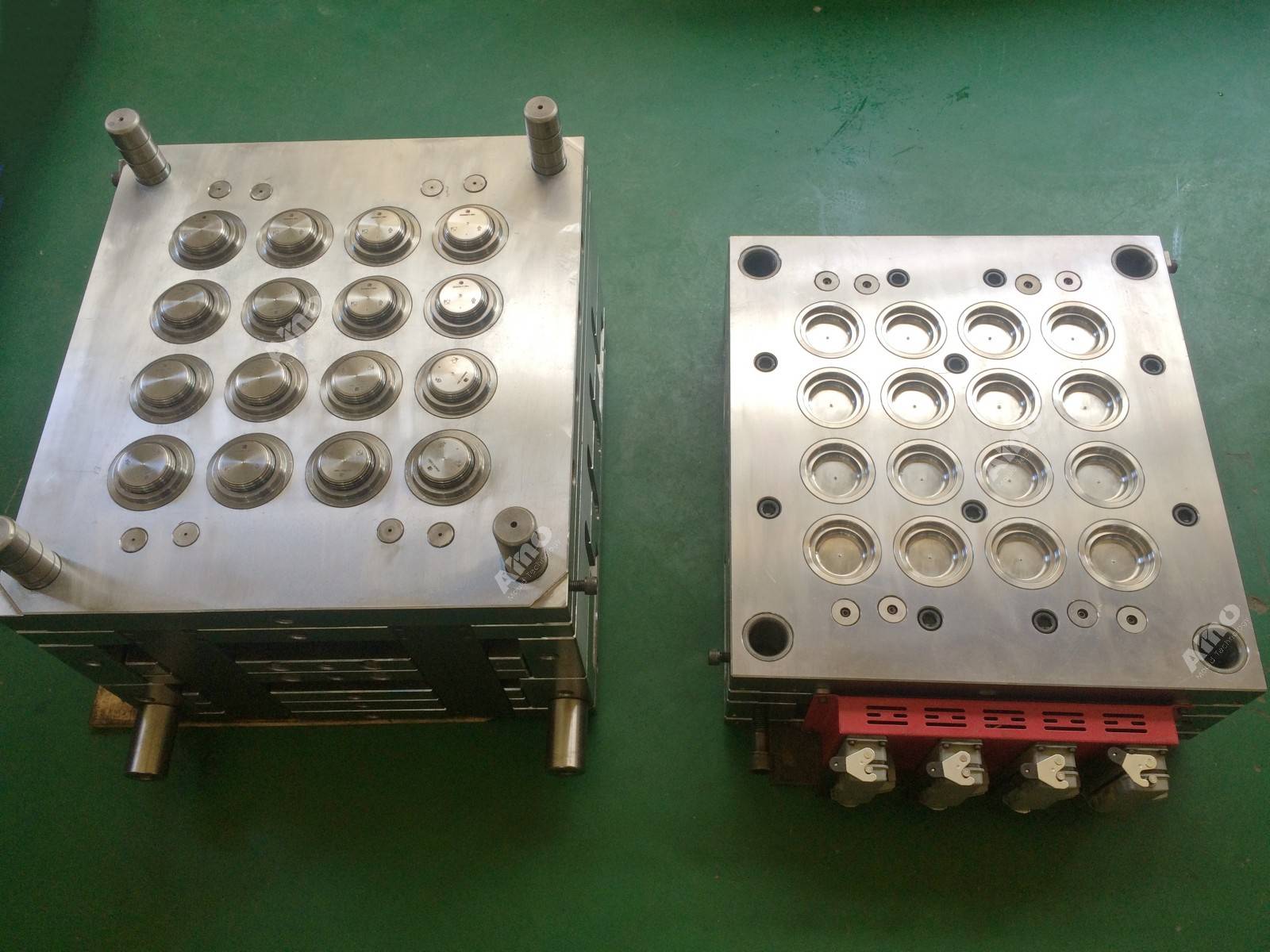

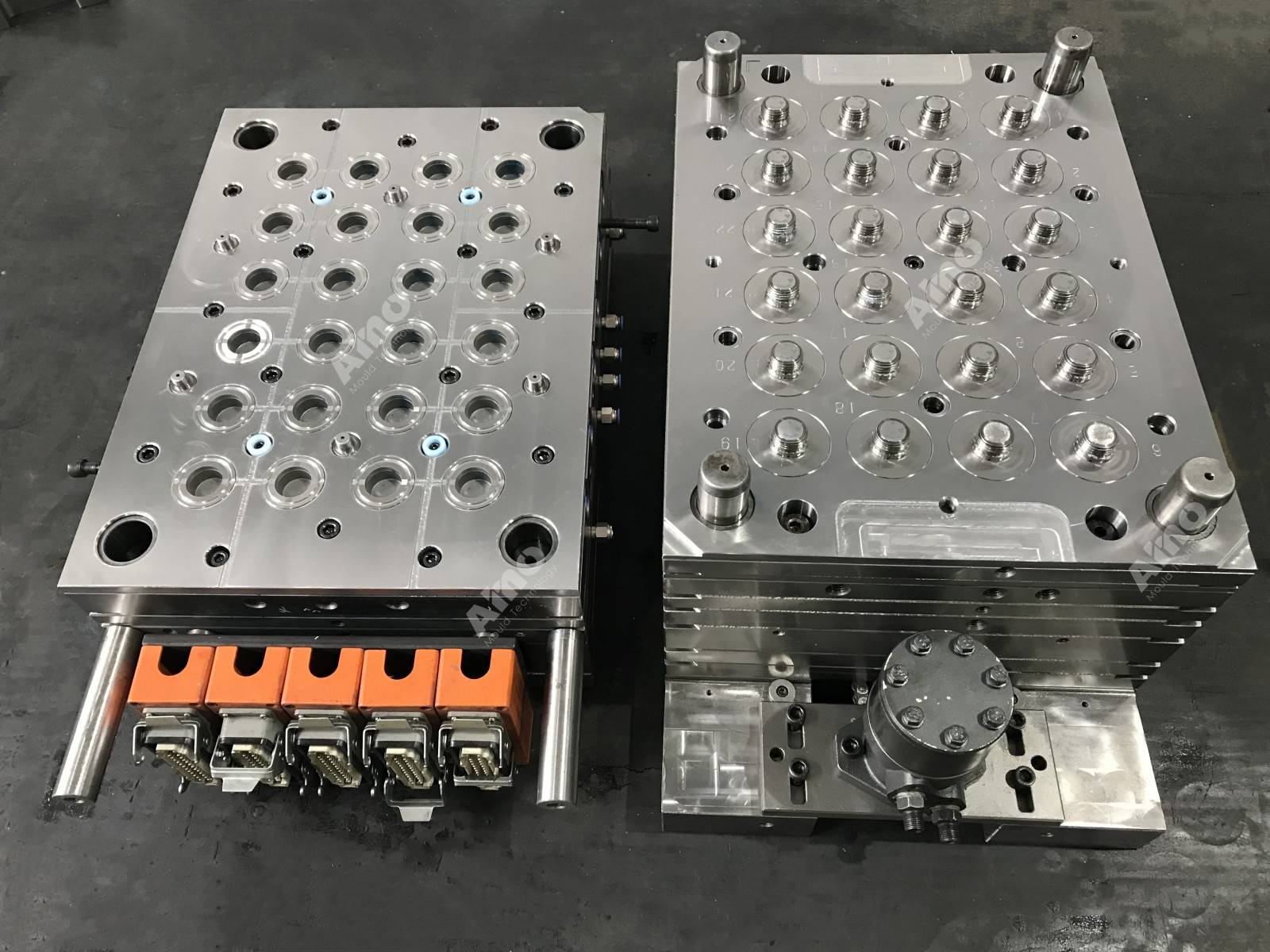

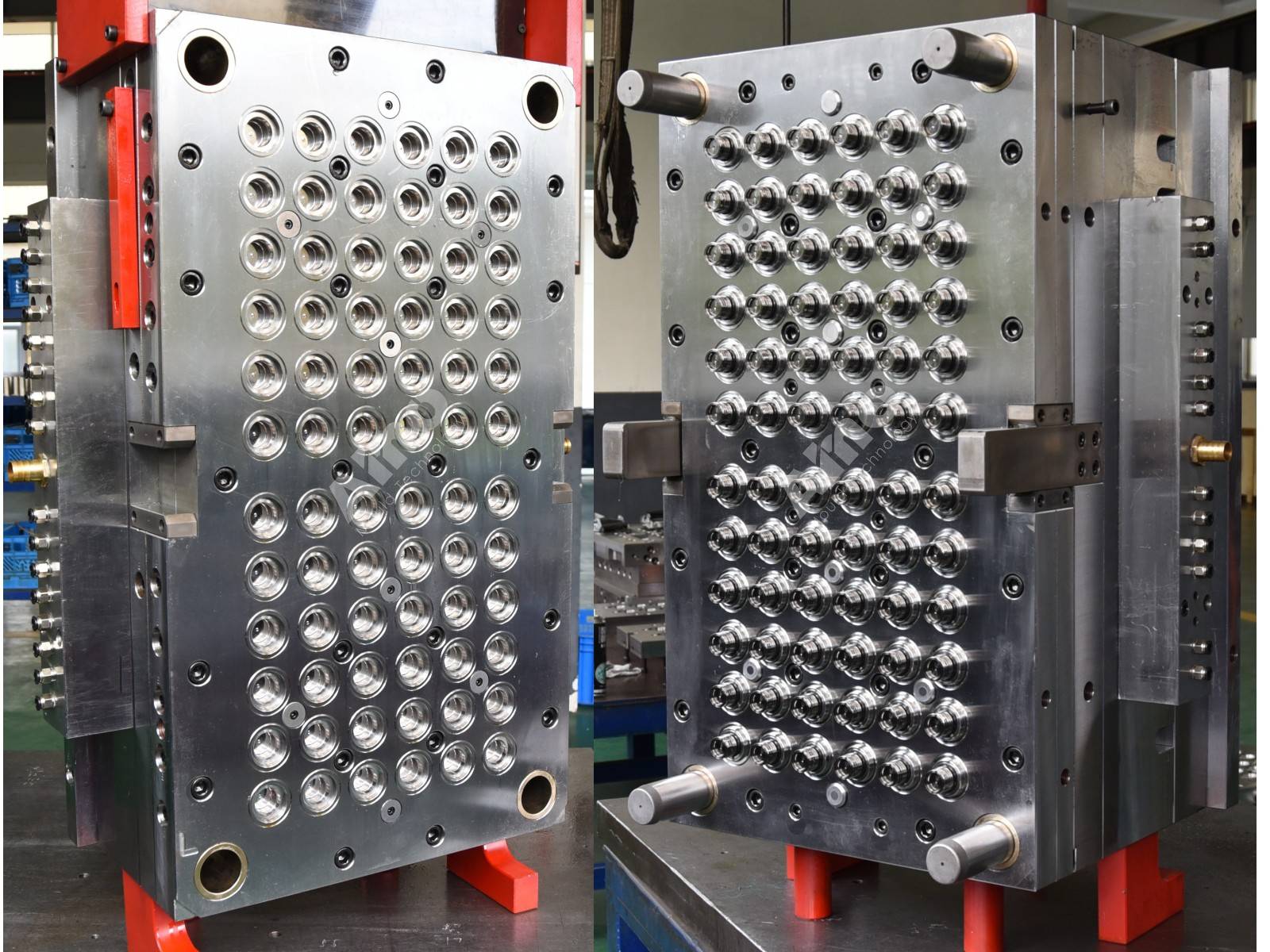

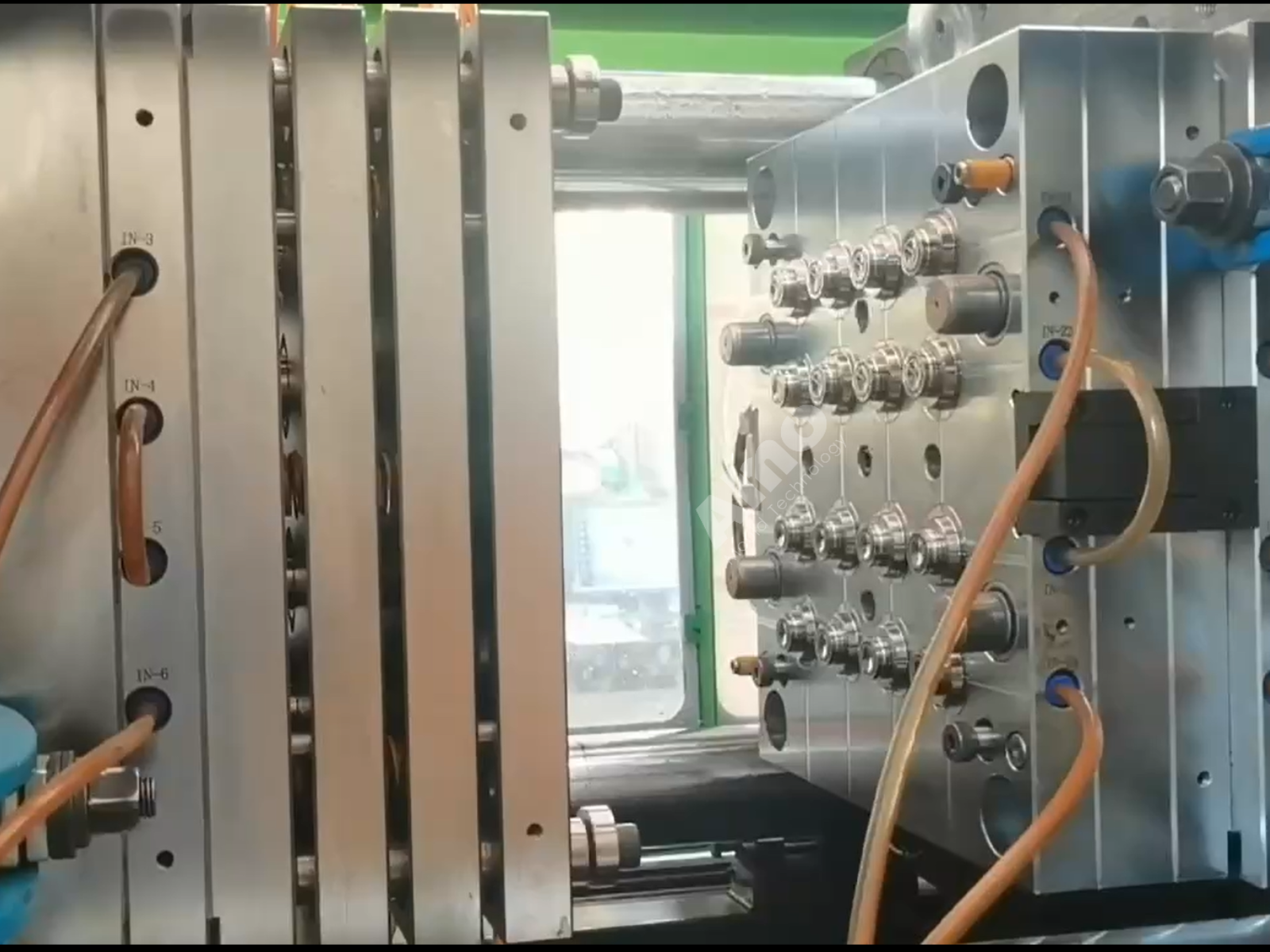

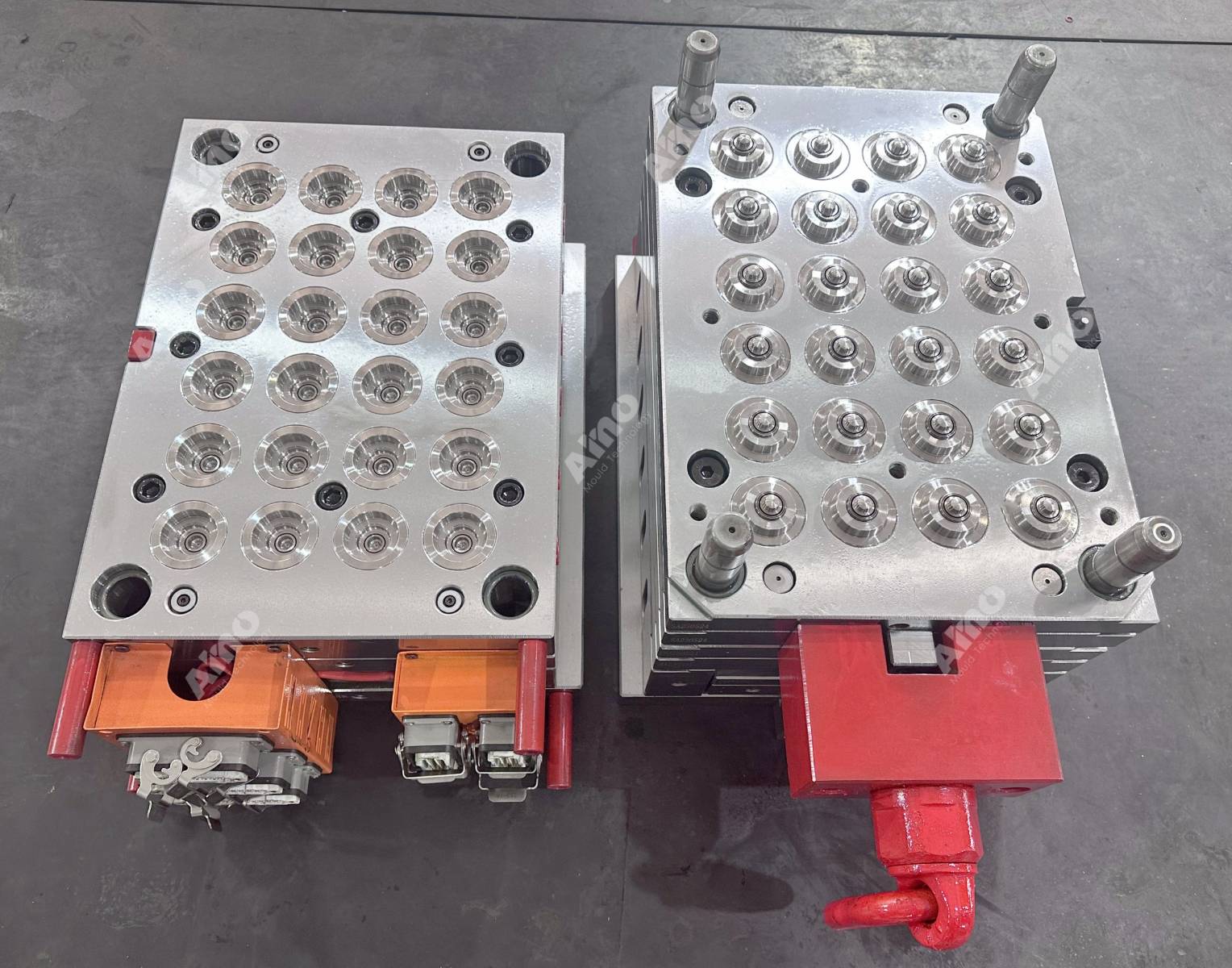

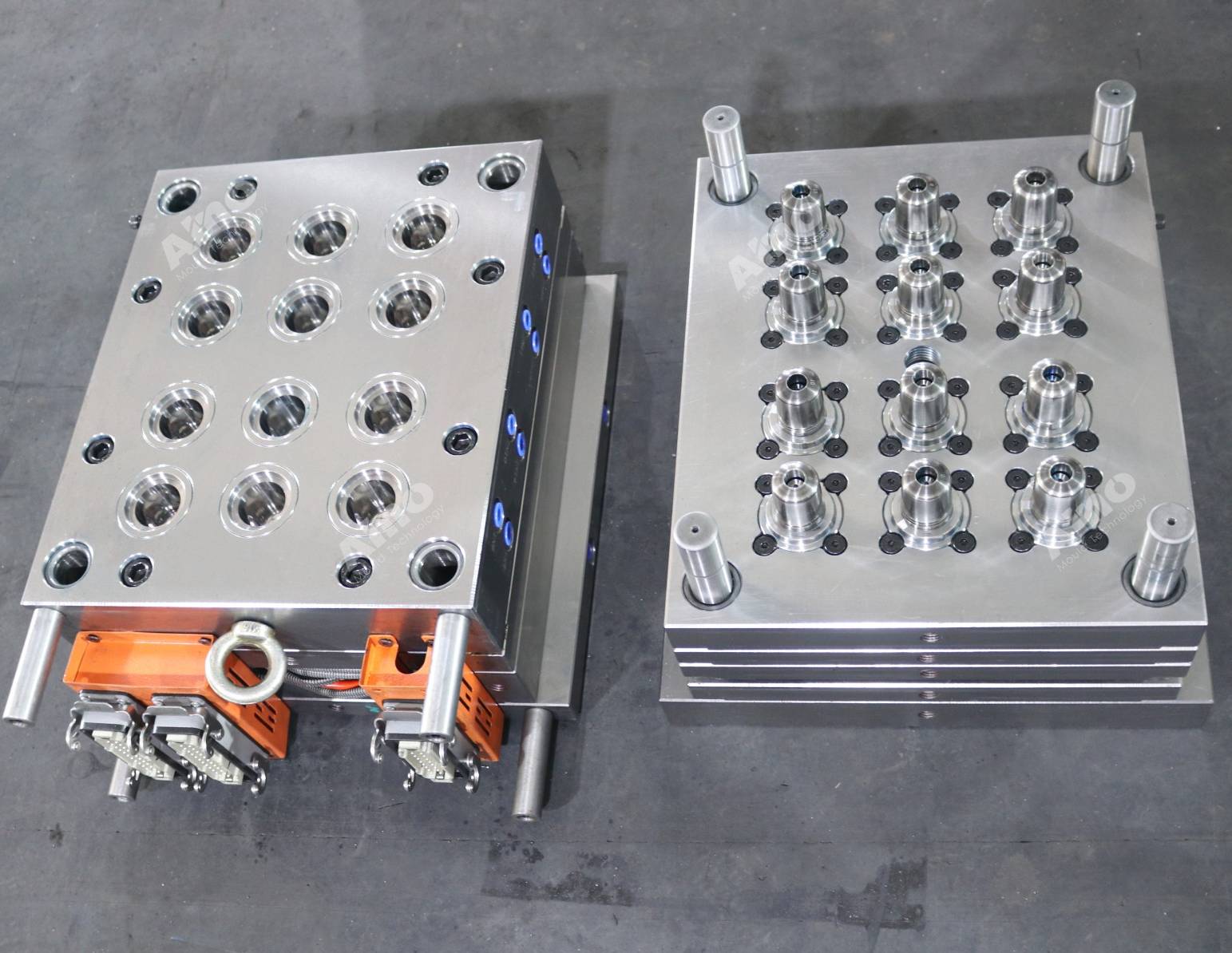

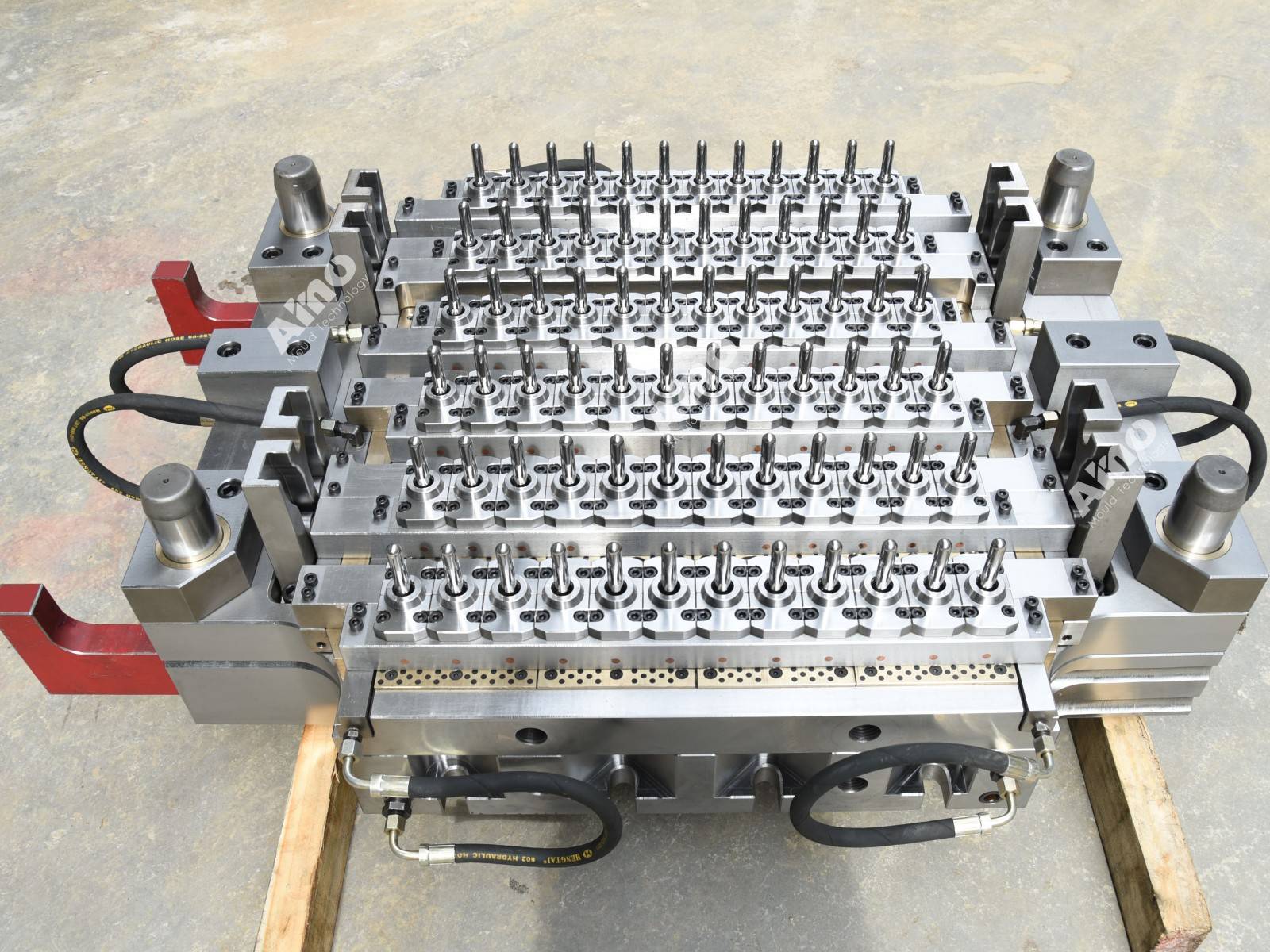

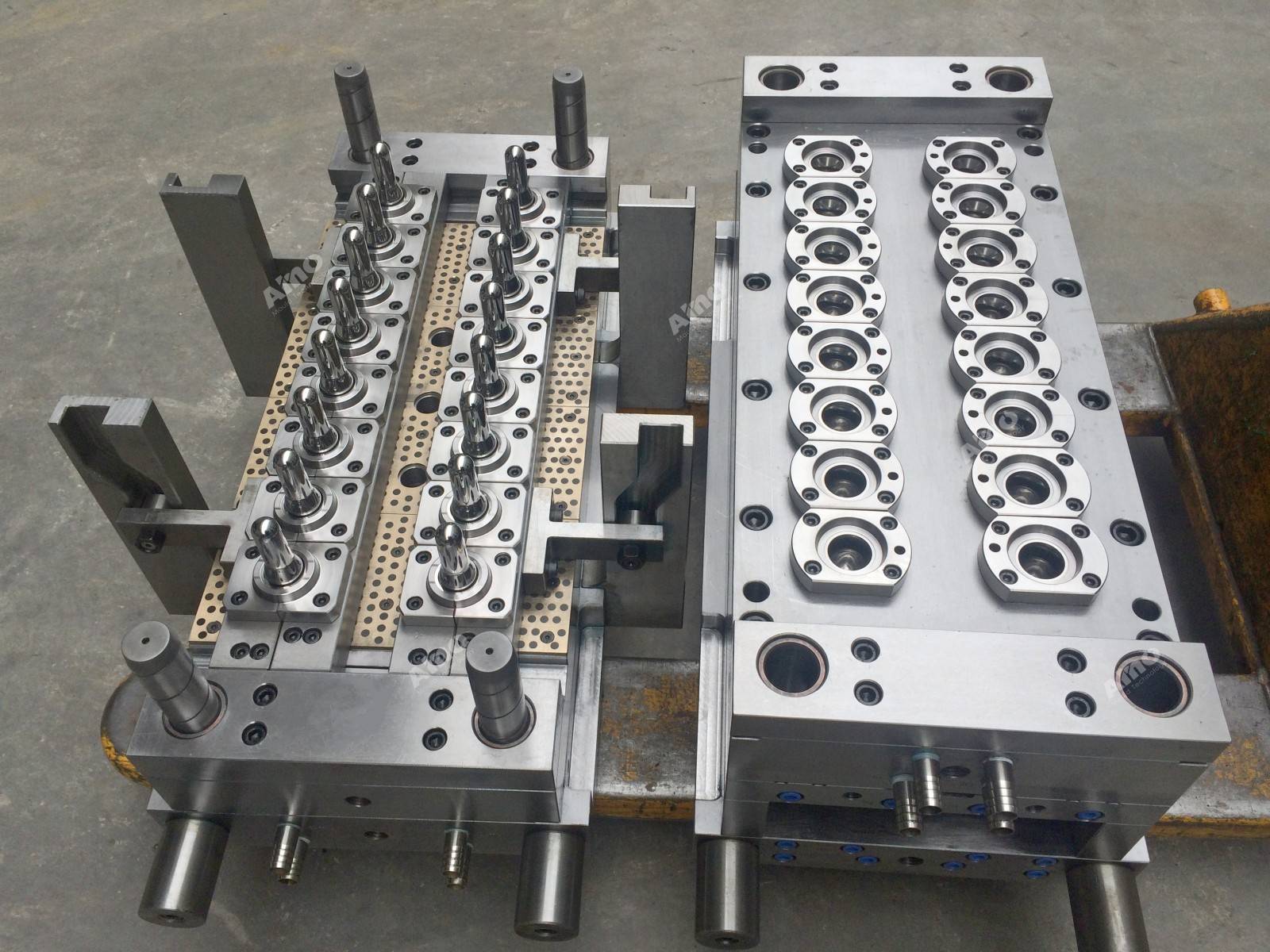

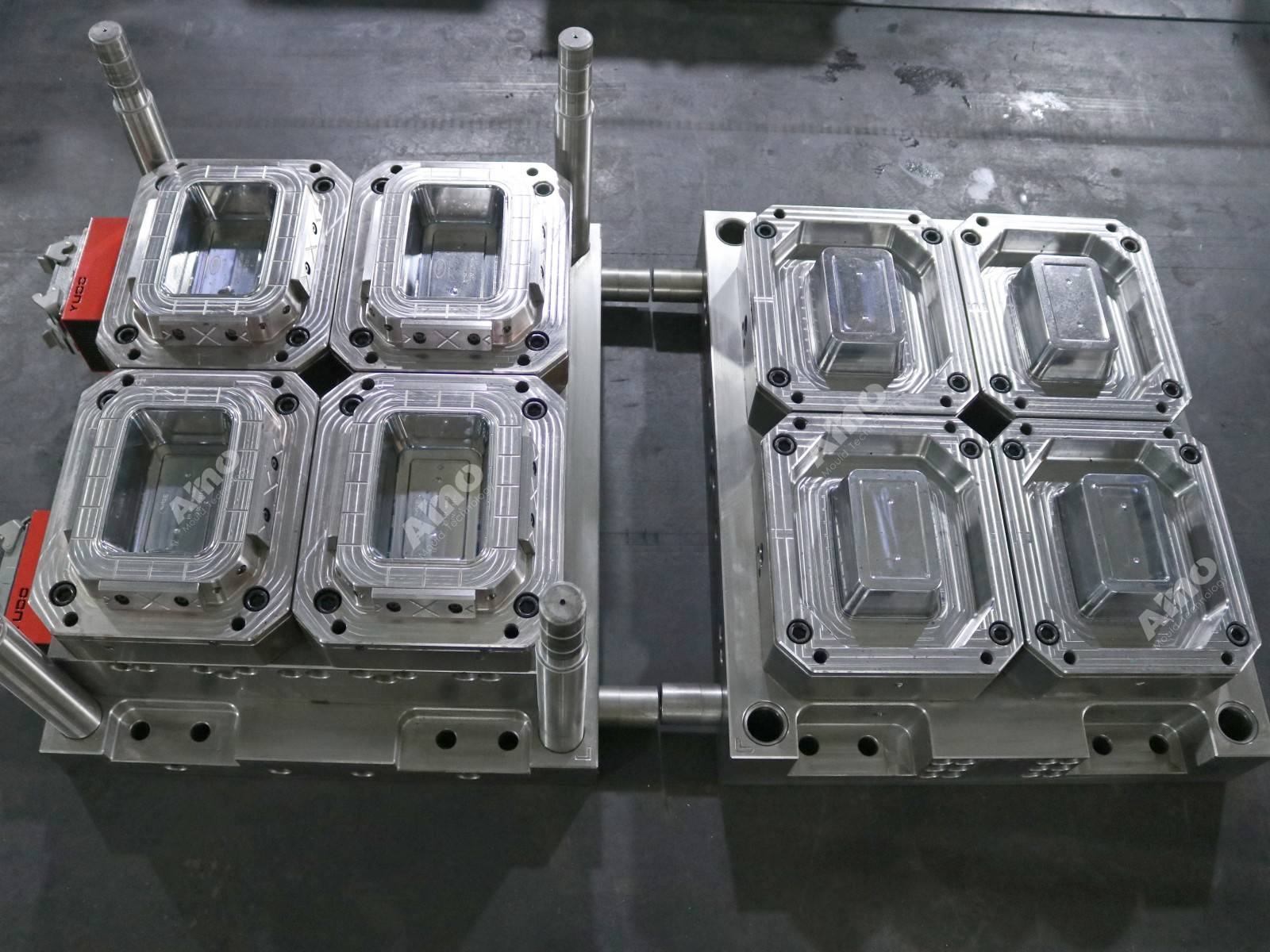

Thinwall lid molds require high-precision tooling to maintain micron-level accuracy. Innovations like needle roller guide units (e.g., FIBRO GmbH’s MILLION GUIDE series) ensure stability and minimize deflection during high-speed stamping or injection molding . These systems are critical for maintaining narrow cutting gaps in applications such as food container lids or semiconductor packaging.

2. CMM Measuring for Quality Assurance

Coordinate Measuring Machines (CMM) validate dimensional accuracy, detecting deviations as small as 1–3 microns. This step is non-negotiable for thinwall molds, where even minor warping can compromise seal integrity. Calibration standards, such as matrix-matched protocols, ensure consistency across batches .

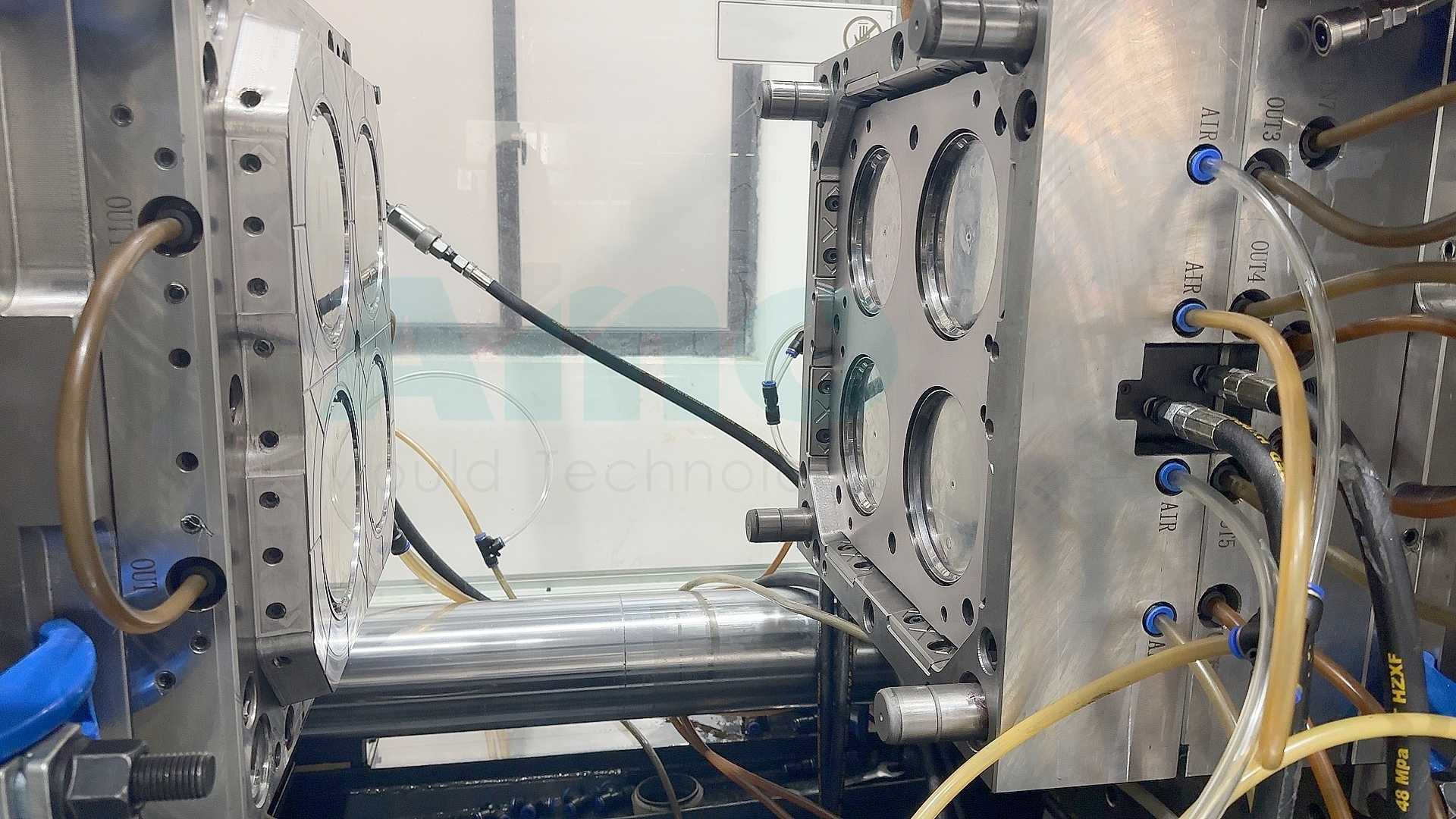

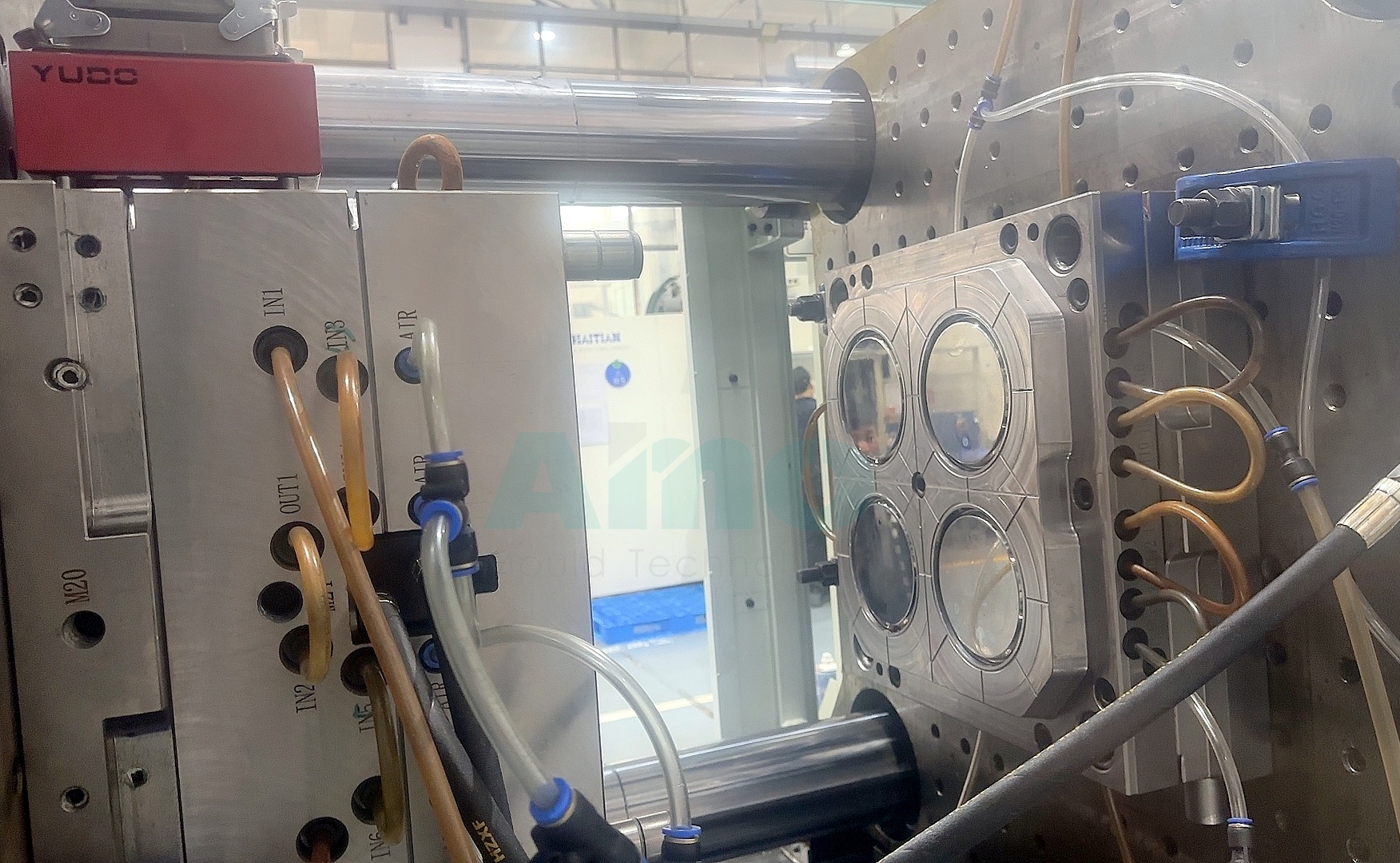

3. Hot Runner Systems & Cycle Optimization

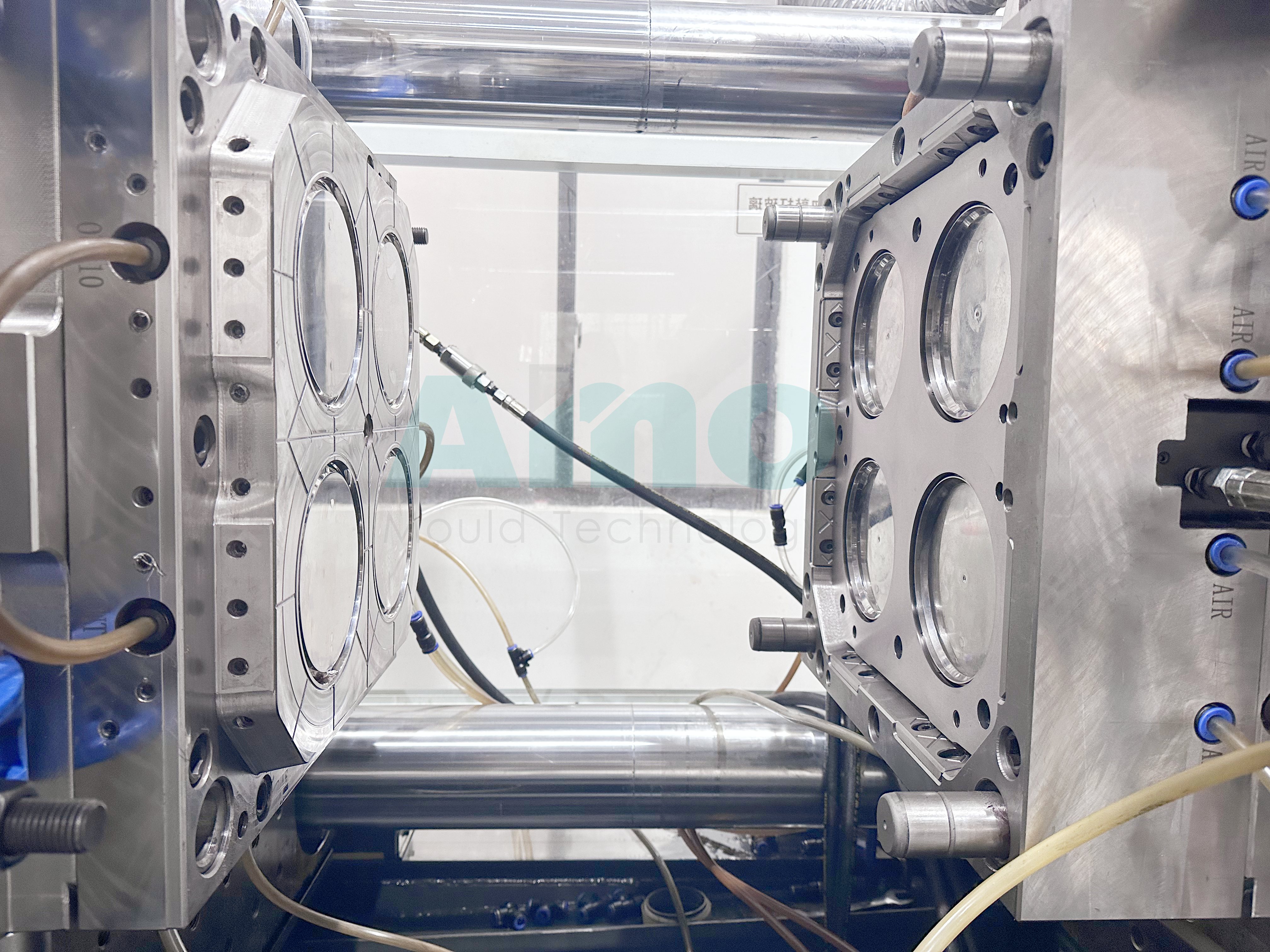

Integrating hot runner systems reduces material waste and cycle times by up to 30%. These systems maintain uniform melt temperatures, critical for preventing flow imbalances in thinwall geometries. For example, multi-cavity molds paired with hot runners are ideal for high-volume dairy or beverage lid production .

4. Zero-Defect Strategies

Achieving zero defects relies on predictive maintenance and real-time monitoring. IoT-enabled molds track parameters like pressure and temperature, while AI algorithms predict wear patterns. Combined with CMM post-production checks, this ensures 99.9% defect-free outputs .

From design to delivery, mastering thinwall lid molds hinges on precision engineering and data-driven quality control. By leveraging technologies like CMM and hot runners, manufacturers can meet rising demands for sustainability and efficiency in global markets.

Specification

| Mould Name | 750ml thinwall lid mold |

| Product Name | thin wall food container |

| Product material | PP |

| Mold Cavity No. | 4cavities |

| Mold Runner System | Yudo hot runner |

| Mold Ejector System | air |

| Mold Running | 5Millions |

| Delivery Time | 55days |

| Mold Feature | can be customized |

Related Products

contact us

Get a Free Quote

Our engineers are available to talk you through each of our offerings. We’ll be sure to reply you within 48hours with detail quotation data. Fill in the form below with as much detail as possible, we’ll get back to you promptly.

SUBMIT